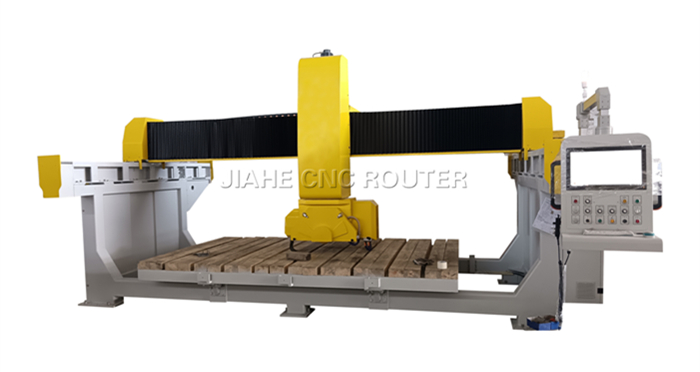

Five-axis Bridge Cutting Machine

Five-axis bridge cutting machine is a high-precision stone cutting equipment widely used in stone processing industries. It is capable of cutting various shapes and sizes of stones with precision and finesse. Below is a detailed product description of the five-axis bridge cutting machine:

Description: The five-axis bridge cutting machine is designed for cutting and shaping stones, such as marble, granite, and other stone materials. It offers precise cutting and shaping capabilities that can meet the requirements of various stone processing projects.

Features:

Five-axis control system for precise cutting and shaping of stones.

High cutting efficiency and accuracy.

Suitable for cutting complex shapes and patterns.

Stable performance with low maintenance requirements.

User-friendly interface for easy operation.

Equipped with advanced cutting tools for high-quality finish.

Specifications:

Cutting dimensions: customizable based on the requirements.

Cutting speed: adjustable for different stone materials.

Maximum cutting depth: up to several centimeters.

Power supply: tailored to the specific needs of the customer.

Control system: five-axis control for precise cutting and shaping.

Applications: The five-axis bridge cutting machine is suitable for a wide range of stone processing applications, including:

Kitchen countertops fabrication.

Monumental stone cutting.

Architectural stone carving.

Artistic stone shaping.

Industrial stone processing.

Benefits:

Precision cutting for intricate stone designs.

Improved efficiency and productivity in stone processing.

Versatile capabilities for different stone materials.

Reduction in material waste.

High-quality finish for stone products.

Overall, the five-axis bridge cutting machine is a versatile and efficient tool for stone processing industries, offering precision cutting and shaping capabilities for a wide range of applications.

Related Products

Submitted successfully

We will contact you as soon as possible