6060 Metal Moulding Machine

6060 metal moulding machine is widely used in the fields of mould manufacturing, saw blade manufacturing, advertising signs, electronics manufacturing and other industries.

Model: JK-4050

Working size: 400*500*300mm

Spindle: 5.5kw water cooled

Control system: Taiwan Syntec

Metal moulding machine is mainly used for machining complicated shapes on copper die, aluminum die and mould steel die.

Technical parameters:

Platform Size (mm) | 400mm* 500mm |

Engraving range (mm) | 400mm* 500mm*300mm |

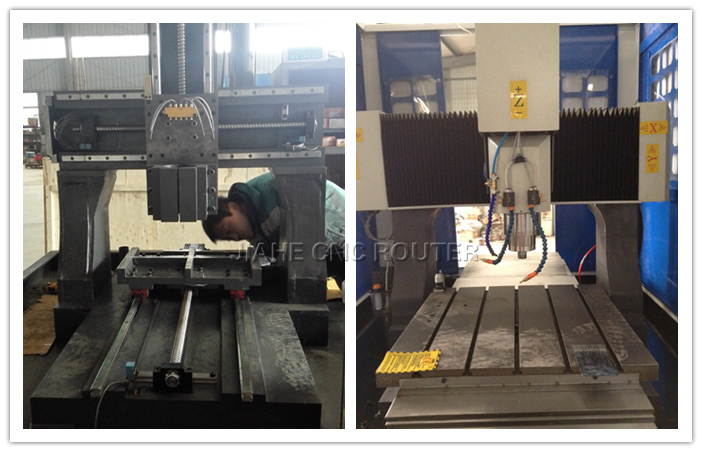

Structure options | Iron struture |

Platform material | Casting iron |

Table fixed type | T-slot table for max fixturing flexibility |

X Axis structure | HIWIN guide rail & 25mm Ball screw |

Z axis traveling height(mm) | 300mm |

Working Voltage | 220V/380V 50Hz/60Hz |

Spindle power (KW) | 5.5KW water cooling spindle |

Spindle speed | 0-24000 (r/ min) |

Max Speed without material | 0-10000 mm/ min |

Max working speed | 0-8000 mm/ min |

X,Y,Z Axis Drive motor | Japanese Yaskawa Servo motor |

Resolution | 0.00625 Pulse |

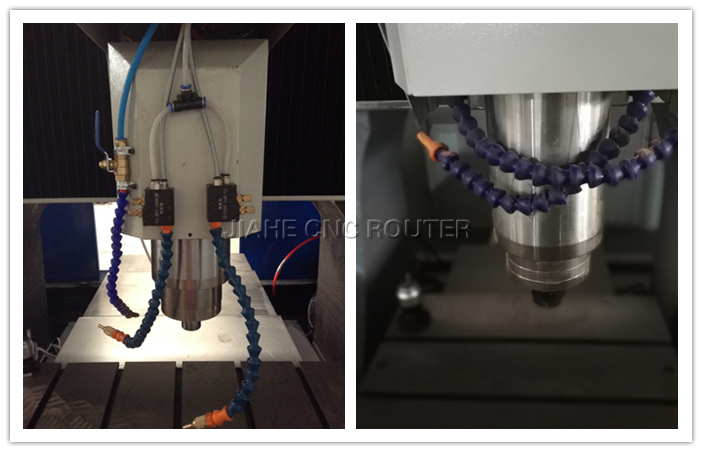

Diameter of cutting tools (mm) | 3.175/ 4.0/ 6.0/ 8.0/ 10/ 12.7mm/16mm |

ATC | Optional |

Control system | Taiwan Syntec Control System |

Code formats | G code, U00, mmg, nc, ENG |

Cooling system | Water cooling |

Features of metal moulding machine:

(1). The machine is completely casting iron body and running desk, very heavy weight. The machine can maintain high precision after long term use and table potential can load 200kgs.

(2.)High torque HQD 5.5kw water cooling spindle motor. The spindle is professionally for steel running with long lifetime, running speed can be 15000rpm-24000rpm.

(3).Control system can use Taiwan Syntec, LNC, Weihong NK200, NK280, Mach3 or Siemens with operation panel and handwheel. The customer can use hand wheel to set tools.

Pictures of metal moulding machine:

Metal moulding machine is suitable for industrial production of copper and aluminum profile parts, small mould processing, and has strong processing ability for wide and deep products.

Related Products

Submitted successfully

We will contact you as soon as possible