Stone Carving Machines in the Decoration Industry

In the decoration industry, the use of stone for various purposes, such as flooring, wall cladding, and decorative accents, has been a popular choice for many years. With advancements in technology, stone carving machines have become an essential tool in the industry, revolutionizing the way stone is processed and enhancing the possibilities for creative designs. This article presents a case study on the application of a stone carving machine in the decoration industry, highlighting its benefits and impact on the overall workflow.

The design team at ABC Decorators worked closely with the client to understand their vision and requirements. They created detailed drawings and digital models of the desired stone carvings, ensuring every intricate detail was captured.

Material Selection: Based on the design specifications, suitable stones were selected for the project. The stone carving machine allows for the use of various types of natural stones, like marble, granite, limestone, or sandstone, depending on the desired aesthetic and durability.

Programming: The digital models from the design phase were imported into the stone carving machine's software. The team programmed the machine to precisely replicate the intricate designs onto the selected stones.

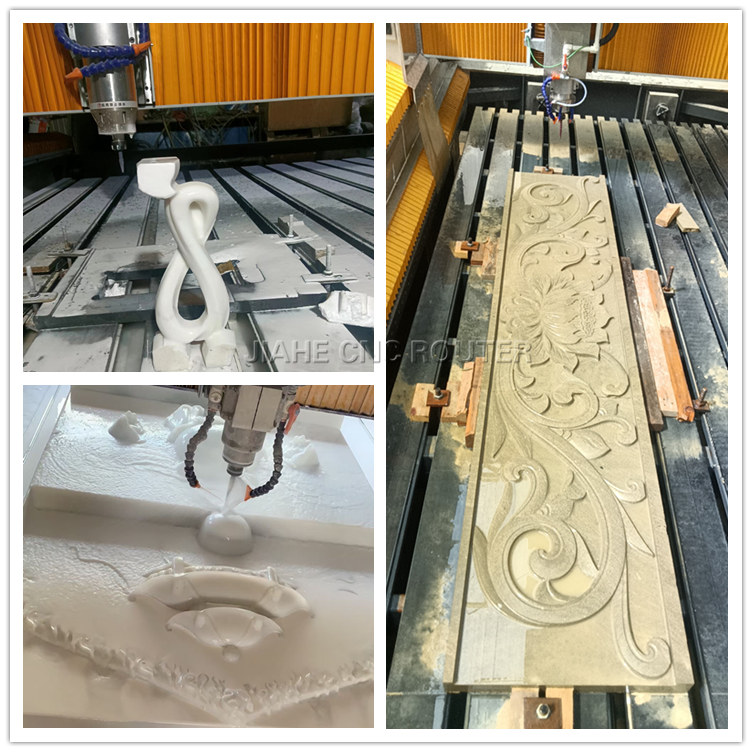

Stone Carving: The stone carving machine then began the process of carving the designs onto the stones. With advanced precision and accuracy, the machine effortlessly executed the complex patterns and shapes, saving time and effort in manual labor.

Finishing: Once the carving process was complete, skilled artisans manually refined the carved stones to achieve the desired texture, smoothness, and finish. This post-processing step added a personal touch and ensured the desired aesthetic quality.