Four Head Woodworking CNC Router Machine

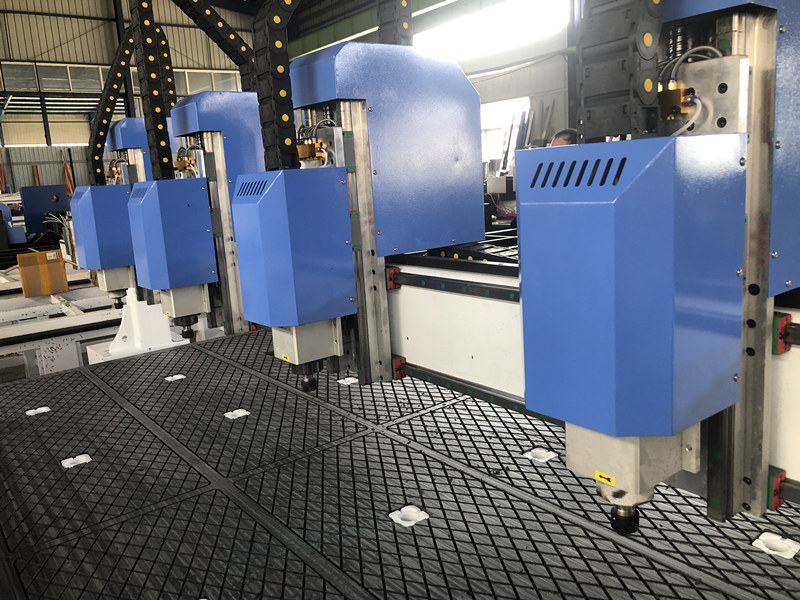

Woodworking CNC Router Machine is an advanced woodworking equipment that boasts several key advantages. Firstly, it has a high level of precision and efficiency in carving and engraving wood. With four independent heads, it can work on multiple pieces simultaneously, greatly saving time and improving productivity.

Model: JK-3015-4

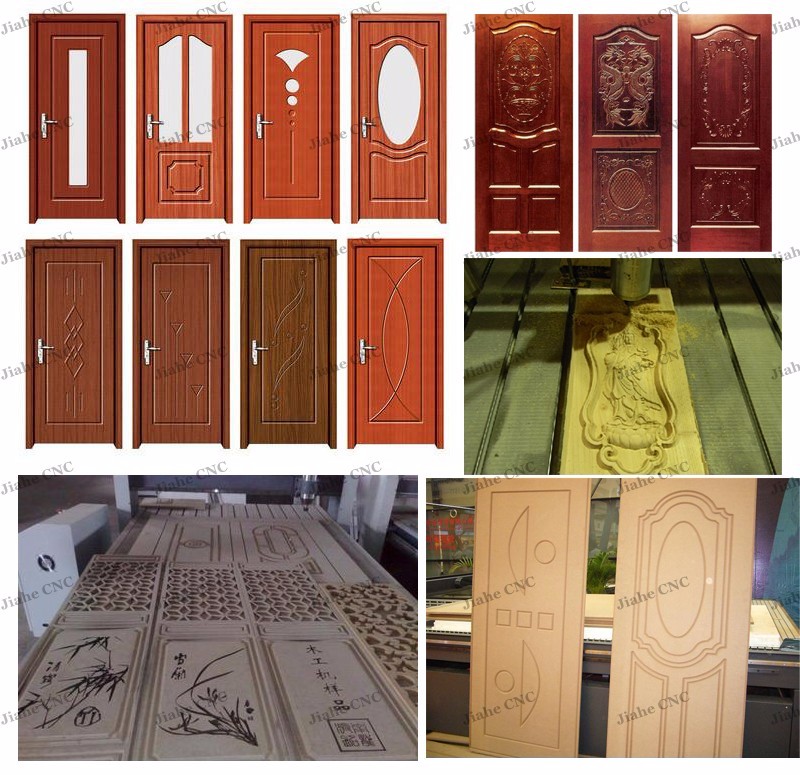

Usage: engraving, cutting, 3D relief, hollow engraving

Working size: 3000mm×1500mm

Each head working area: 750mm×1500mm

Woodworking CNC Router Machine is equipped with high-performance spindle motors that enable it to achieve precise and smooth cutting, carving, and engraving results. The four-head design allows for simultaneous carving, which enhances efficiency and maximizes productivity.

Technical parameters of woodworking CNC router machine:

Model No. | JK-3015-4 |

Working size | 3000×1500×300mm |

Working size of each head | 750×1500×300mm |

Machine structure | Thick steel welded structure |

Transmission | Helical gear racks for XY axis,ball screws for Z axis |

Rails | Linear square guide rails for all axis |

Spindle | 3.5kw air cooled spindle*4pcs |

Inverter | 3.7kw inverter*4pcs |

Motors and drivers | Leadshine hybrid servo motors&drivers,Z axis with brake |

Control system | NK105 DSP control system |

Working table | Aluminum and PVC T-slot table |

Dust collector | 3kw double bag dust collector |

Lubrication system | Auto lubrication system |

Voltage | 380V 3 phase |

Packing size | 2200×3800×1800mm |

N.W. | 1400kgs |

G.W. | 1500kgs |

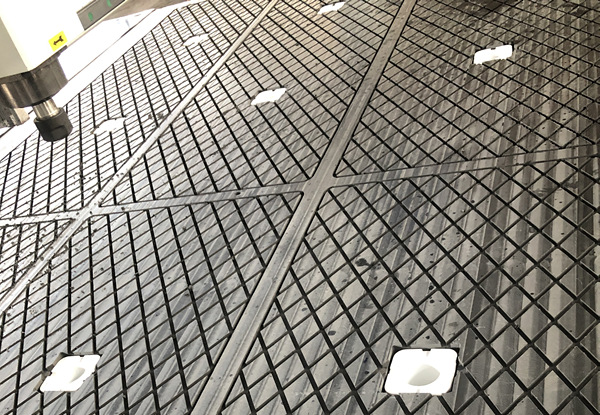

Parts show of woodworking CNC router machine:

Vacuum working table, convenient for fixing material.

Air cooled spindle motor for woodworking application only

Accessories with the machine

Applications and Materials: Four Head Woodworking CNC Router Machine can be widely used in various industries, such as furniture manufacturing, wooden crafts production, and interior decoration. It is suitable for carving intricate designs, patterns, and reliefs on materials like solid wood, plywood, MDF, particleboard, and other wood-based panels. The machine allows for customization and personalization in the woodworking industry, enabling craftsmen to bring their creative ideas to life.

Related Products

Submitted successfully

We will contact you as soon as possible