CO2 laser marking machine is suitable for marking paper, rubber, acrylic, glass, ceramics, plastics, leather, cloth, wood, and many other non-metallic materials.Technical parameters of Co2 laser marking machine: ModelJK-CLM10JK-CLM30JK-CLM60Power10W30W60WWavelength9.3um~10.6umMinimum Line Width0.1mmTotal Power<500W<500W<2000WBeam Quality<1.3M2<1.5M2<1.5M2Spot Diameter0.03mmFrequency1-50KHz1-50KHz1-80KHzPower Adjustment Range10-100%Engraving Speed≤7000mm/sCooling MethodAir coolingOperating Environment10℃~35℃ ( No condensation)Electricity Demand220V / 50Hz (110V/60Hz)

Contact Now

CO2 laser engraving machine can process an extensive range of materials, including wood, leather, plastic,glass, paper, etc. The performance of CO2 laser engraving machines is exceptional, with high engraving speed, productivity, and flexibility. Features of CO2 laser engraving machine:1. Highly precise and accurate2. Non-contact processing - this ensures that even the most delicate materials are not damaged during the engraving process3. High-speed processing - can engrave materials at significantly faster speeds compared to traditional engraving tools.4.

Contact Now

Acrylic laser cutting machine is a high-efficient tool that uses the laser beam to cut or engrave acrylic and other non-metallic materials.

Contact Now

Laser Cutting Machine For Acrylic is primarily used for cutting acrylic materials of varying thicknesses. Additionally, it can also cut other non-metallic materials, such as wood, rubber, leather, and paper, providing versatile cutting options.Advantages of laser cutting machine for acrylic:High-Precision Cutting: The acrylic laser cutting machine employs advanced laser technology, providing precise and smooth cuts.

Contact Now

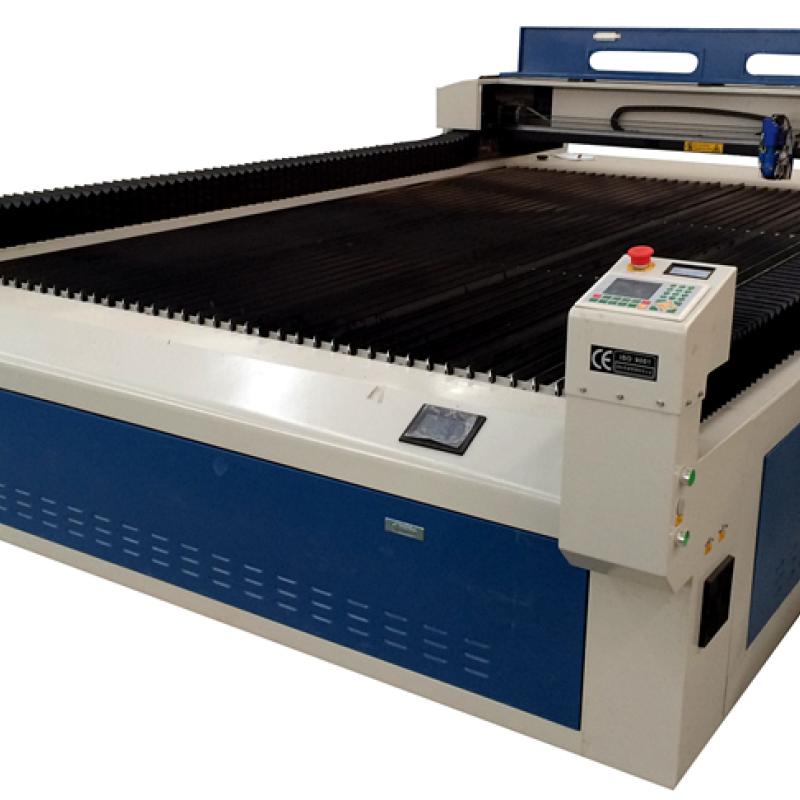

Co2 laser cutting machine for metal and non metal main components include a laser beam, control panel, power supply, laser head, reflector, and lens. The machine uses a high-powered CO2 laser beam to cut materials.

Contact Now

Co2 laser cutting machine features a large cutting area of 1.3 x 2.5 meters, which makes it suitable for cutting large sheets of material and it is equipped with a powerful laser that can cut through a wide range of materials quickly and accurately.Features of co2 laser cutting machine: 1. Precision cutting: The machine offers exceptional precision, allowing you to create intricate designs and shapes with ease.2. Versatility: The machine can cut a wide range of materials, including metals, plastics, composites, wood, and acrylics.3.

Contact Now

CNC router machine for acrylic cutting is high-tech equipment used to cut acrylic sheets with high precision, accuracy, and efficiency. The machine comes equipped with advanced software and hardware that allow users to create intricate and complex designs with ease. The machine typically has a working area of 1500mm x 2500mm, which provides ample space to work on large sheets of acrylic.Features of CNC router machine for acrylic cutting:1. High-speed cutting and engraving capabilities.2. User-friendly interface and intuitive software for easy operation.3.

Contact Now

Small laser engraving machine is a compact and portable machine, which is easy to operate and requires minimal maintenance.

Contact Now

Mixed laser cutting machine with a working area of 1300mm x 900mm can cut a variety of materials including metal, acrylic, wood, MDF, leather, fabric, and many more. So, it is widely used in industries like advertising, decoration, metal processing, IT, and handicrafts.Technical parameters of mixed laser cutting machine: 1Working area1300mm x 900mm2Laser power130W RECI3Engraving speed0-64000mm/min4Cutting Speed0-36000mm/min5Preposition accuracy±0.1mm6Cutting PlatformBlade or Honeycomb table7Driving systemStepper motors8Cooling modeCirculating-water cooling and protection system9Minim

Contact Now

Laser cutting and engraving machine is suitable for cutting and engraving various of materials, such as acrylics, PVC, wood and plywood, glass and ceramics, fabrics and leather, etc. Features of laser cutting and engraving machine:- High level of precision and accuracy- User-friendly software interface and easy to operate- Minimal maintenance required- Quick turnaround time for engraving projects- Cost-effective compared to traditional engraving methodsTechnical parameters of laser cutting and engraving machine:ItemJK-1390L Engraving Area1300 X 900mmLaser Power80W/100W/130W

Contact Now

Stone laser engraving machine is specialized device used for carving designs, texts, and patterns onto a wide range of natural stones, including marble, granite, basalt, sandstone, and limestone. Advantages of stone laser engraving machine: 1. Speed and Efficiency - Stone laser engraving machines are incredibly fast and efficient as compared to the traditional manual carving methods. They complete complex designs in minutes or hours rather than days.2. High Precision - Accuracy is key in stone carving, and laser technology has it all.

Contact Now

Industrial 4x8 marble granite stone laser engraving machine for sale is suitable for engraving a wide range of materials, including marble, granite, and other stone materials. It is widely used in the construction industry, interior design, and other fields that require high-quality engraving of stone materials.Features of industrial 4x8 marble granite stone laser engraving machine for sale: Industrial 4x8 marble granite stone laser engraving machine for sale has a large engraving area, providing ample space for intricate designs.

Contact Now

Fiber laser marking machine uses a laser beam to create permanent marks on the surface of different materials. The machine can achieve high-speed and high-accuracy marking by using a fiber laser and advanced optical scanners. The laser beam generated by the machine is of high quality and can produce marks with a resolution of 0.001mm.

Contact Now

Desktop mini CNC engraving machine can engrave and cut a wide range of materials, including wood, plastic, acrylic, PVC, and soft metals. The machine is equipped with a high-quality stepper motor that ensures the accuracy and consistency of the engraved design. The machine is also equipped with a cooling system that prevents overheating during prolonged use. Desktop mini CNC engraving machine has a compact design that makes it easy to use in small spaces. The machine is made of high-quality casting aluminum that ensure durability and reliability.

Contact Now

1500w Laser Welding Machine supports welding of various materials, including but not limited to stainless steel, aluminum, copper, and titanium. It is suitable for welding thin and thick materials, allowing for a wide range of applications in industries such as automotive, aerospace, electronics, and jewelry manufacturing.Advantages of 1500w laser welding machine: High Precision: The machine employs advanced laser technology to enable precise and accurate welding.

Contact Now

CNC wood engraving machine with automatic tool changer is perfect for a variety of industries, including furniture making, decoration, crafts, advertising, and more. It can handle a variety of materials, such as wood, MDF, acrylic, and PVC.Advantages of CNC wood engraving machine: 1. Automatic Tool Changing Function: This CNC wood engraving machine has an automatic tool changing function, which can store and automatically change up to 12 different carving tools, allowing for a seamless and hassle-free carving process.2.

Contact Now

6060 metal engraver is applicable for aluminum, acrylic, wood and plastic, etc.

Contact Now

30W laser marking machine is a powerful tool that can be used to mark various materials, such as metal, jewellery, and more. Its high speed, precision, and efficiency make it an essential tool for various industries, while its low maintenance and energy-saving features make it a sustainable choice. Advantages of 30w laser marking machine: 1. High Speed and Efficiency30W laser marking machines are designed to work faster and more efficiently. With the use of fiber optic technology, the laser beam can be rapidly manipulated to mark the material without damaging it.2.

Contact Now

2000w laser welding machine is suitable for welding many kinds of materials, including stainless steel,carbon steel, copper, aluminum, nickel, titanium etc. Features of 2000w laser welding machine:- Steady output, suitable for long-term welding- Laser spot can be adjusted according to the welding requirements- Easy to operate, convenient for small batches or small parts welding- Uniform and stable energy distributionTechnical parameters of 2000w laser welding machine:ModelJK-HW-1000JK-HW-1500JK-HW-2000JK-HW-3000Laser Power1000watt1500watt2000watt3000wattLaser SourceFiber Laser Manufa

Contact Now

1000W Fiber Laser Machine is suitable for a wide range of applications in industries like automotive, medical, aerospace, and electronics. It can be used to cut various materials like metal sheets, pipes, tubes, plastics, ceramics, and more.Advantage of 1000W Fiber Laser Machine:1. High Precision: 1000W Fiber Laser Machine is equipped with a high precision laser system that can deliver precision cuts with excellent edge quality. This ensures that the end products are of a high-quality finish.2.

Contact Now

Desktop laser marking machine is suitable for marking various non-metallic materials such as paper, plastic, leather, glass, ceramics, etc.

Contact Now

Laser welding machine 200W is suitable for welding a wide range of materials, including precious metals like gold and silver, as well as titanium, stainless steel, and other alloys commonly used in jewelry-making.Features of laser welding machine: (1).

Contact Now

YAG laser welding machine is suitable for welding a wide range of materials, including precious metals like gold and silver, as well as titanium, stainless steel, and other alloys commonly used in jewelry-making.Advantages of YAG laser welding machine:(1).

Contact Now

50w fiber laser marking machine is an advanced equipment widely used in industrial marking field. It utilizes fiber laser beam to mark on various materials with high precision and speed, such as stainless steel, carbon steel, aluminum, copper, brass and gold. Features of 50w fiber laser marking machine:1. High efficiency and high speed marking with no consumables required2. Permanent marking, resistant to abrasion and corrosion3. Non-contact marking process, no damage to the material surface4. Wide range of applications on various materials, shapes and sizes5.

Contact Now